Unlocking Industry 4.0 in UK Manufacturing

Unlocking Industry 4.0 in UK Manufacturing

Leveraging Synel Solutions for Workforce Management and Access Control

Executive Summary

As UK manufacturing continues to face pressure from global competition, supply chain disruptions, and workforce challenges, including how to attract and retain the best employees, the need for smarter, more agile operations has never been more pressing.

With Smart Industry, we digitise shifts to drive productivity using measures such as quantity, quality, efficiency and production offset to reach greater levels of automation and time saving smart-tech.

The term Industry 4.0 refers here to a development strategy or pathway for the integration of digital technologies such as IoT (Internet of Things), AI (Artificial Intelligence), robotics, and cloud computing into manufacturing.

This whitepaper explores the evolution of Industry 4.0 in the UK, the transformative potential it brings, and how Synel's workforce management and access control solutions support manufacturers in achieving full digital integration, compliance, and operational excellence.

1. Introduction: The Changing Face of UK Manufacturing

UK manufacturing has long been a cornerstone of the national economy, contributing approximately £224 billion annually and employing over 2.6 million people. However, the sector is in flux:

Rising energy and material costs

Increased National Insurance and business tax burdens

Skills shortages and an aging skilled workforce coupled with an orbit pull of skilled workers to country-wide and Global centres

Post-Brexit and other regulatory changes

A global push for sustainable production where new frameworks in business demand such policies

To remain competitive, UK manufacturers must embrace Industry 4.0 with intelligent and connected automation for honing production or risk a disconnect from current trends in the economy impacting on their bottom line.

2. Understanding Industry 4.0

Before the current 4.0 Industrial Revolution characterised by cyber-physical digital technology, connectivity and automation with “smart factories” with data driven decision making what came before was:

Industry 1.0; Late 1700s to Early 1800s Mechanisation with Steam and Waterpower

Industry 2.0; Late 1800s to Early 1900s Electric, Gas & Oil Power with Mass Production

Industry 3.0; Late 20th Century Automation and Digital Technology with Lean Manufacturing

Industry 4.0 marks this fourth industrial revolution, characterised by:

Cyber-Physical Systems (CPS)

Industrial Internet of Things (IIoT)

Big Data and Analytics

Cloud and Edge Computing

Smart Automation and AI

These technologies drive a shift from traditional, linear manufacturing to smart factories which provide dynamic, responsive, and data-driven operations.

Key Benefits for Manufacturers:

Real-time monitoring and decision-making

Predictive maintenance and reduced downtime

Personalised, high-mix production capabilities

Enhanced supply chain integration

Improved energy efficiency and sustainability

3. The UK Industry 4.0 Landscape

Despite clear advantages, the adoption of Industry 4.0 in the UK has been slow:

Larger enterprises often lead in digital transformation

SMEs face budget and skill barriers

Many manufacturers still rely on legacy systems

Uncertainty in the marketplace

The UK government and initiatives like Made Smarter aim to accelerate adoption by offering guidance, funding, and partnerships. However, a significant barrier remains with integrating digital technologies across all layers of the organisation, including workforce and facility management.

4. Workforce Transformation: A Critical Enabler

Human capital is central to Industry 4.0. While automation increases productivity, it also reshapes the workforce:

New digital skills are required

Flexibility in shift patterns and roles becomes critical

Compliance with safety and workforce regulations must be ensured

To thrive in this environment, manufacturers need advanced tools for managing human resources alongside machines and data systems. This is where Synel’s integrated solutions can lead the way.

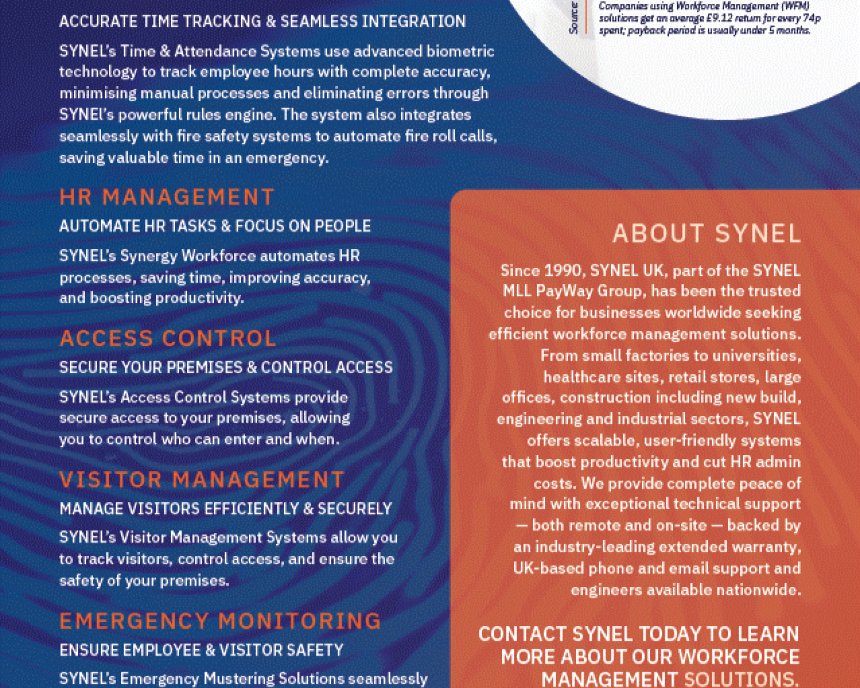

5. Synel: Powering Smart Workforce and Facility Management

Synel UK provides cutting-edge solutions that align seamlessly with Industry 4.0 principles by offering real-time, data-driven platforms for workforce management and access control.

5.1 Workforce Management with Synel

Synel's workforce management system (WFM) transforms HR and operations through:

Cost & Efficiency Tracking via Time & Attendance Real-time monitoring of employee hours, absences, and productivity via biometric and mobile clocking.

Human Resource Deployment and Roster Planning AI-enhanced scheduling to match production demand with the available workforce.

Compliance and Audit Trail Ensures adherence to Working Time Directive, GDPR, and Health & Safety standards.

Remote & Hybrid Work Management Supports flexible arrangements while maintaining visibility and accountability.

Integration with Third Party Solutions: Payroll, ERP & HR Systems Real-time sync with systems like SAP, Oracle, IRIS, and Sage, but to name a few, for unified operations. Added to that, the Synel Open API allows for data flexibility in how a solution needs to integrate into your digital ecosystem

Impact on Industry 4.0 Goals in Manufacturing:

Data-driven workforce optimisation

Reduced downtime through better shift alignment

Increased workforce flexibility and morale

Transparent, auditable data for regulatory compliance

5.2 Access Control for Smart and Secure Facilities

In an era where cybersecurity and physical security converge, Synel’s access control systems provide:

Biometric & RFID Authentication Prevents unauthorised access to sensitive areas and machines.

Hierarchical, Zonal & Time-Based Access Restricts or enables access based on job roles, shifts, or training certifications.

Integration with CCTV and Alarm Systems Offers unified physical security infrastructure.

Emergency and Visitor Management Automated Real-time evacuation lists, guest tracking, and contactless entry.

Benefits for Industry 4.0 Environments:

Enhanced safety and reduced risk of human error

Audit-ready logs for compliance and insurance

Integration with smart building systems (lighting, HVAC)

Protection of digital and physical IP

6. Real-World Applications: Synel in UK Manufacturing

Several UK manufacturers have already deployed Synel solutions to:

Replace manual timesheets with automated T&A, reducing payroll errors by over 90%

Enhance facility security across multi-site operations with centralised access control

Manage workforce mobility across hybrid and flexible work models

Enable compliance with ISO and HSE audit requirements effortlessly

7. Conclusion: Synel as a Strategic Partner in the Industry 4.0 Journey

Industry 4.0 is not just about machines and data. It’s about the people, the processes undertaken and the platforms used. For UK manufacturers looking to embrace this revolution, Synel offers the foundational digital infrastructure to manage the human side of the smart factory.

With scalable, integrated, and secure solutions, Synel empowers manufacturers to:

Streamline operations

Future-proof workforce planning

Meet compliance demands

Create a safer, smarter working environment

By aligning your workforce and facility management with your Industry 4.0 roadmap, Synel ensures that your digital transformation is complete and ready for the changes that happen in the future.

About Synel UK

Synel UK is a leading provider of workforce management, access control, and visitor management solutions. With over 30 years of experience and a strong presence in UK manufacturing, Synel helps organisations optimise performance, ensure compliance, and unlock the full value of their workforce. Free Industry 4.0 Consultation

Synel UK are currently offering free consultations if you are curious to see how you can uncover the value of adding your workforce management into your Industry 4.0 business strategy.

This is with no obligation so you can benefit from hearing insight of how we could help you to strategise workforce management into 2026.

To send one of our 4.0 Consultants an enquiry please follow this link; https://syneluk.zoholandingpage.eu/consultation/